Cost Reduction Proposals

Cost reduction of thermal equipment

We perform thermal diagnosis based on accurate heat balance and heat transfer calculations to improve heat utilization and problem-solving. We assess cost reduction effects based on proposals for heat recovery (steam condensate recovery, etc.). We perform thermal diagnosis using thermography, calculate cost reduction effects (fuel cost reduction) from insulation, and compare insulation costs.

Boiler Improvement

Boiler fuel consumption improvement, efficiency improvement, through flow boiler, etc.

Refresh Air Conditioners and Heat Exchangers

Refresh with regular cleaning! Insufficient capacity due to dirt leads to a waste of energy.

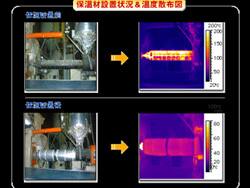

Thermal Diagnosis

Thermal diagnosis using thermography reduces heat that is being wasted and provides cost-reduction proposals.

(Cooperation: NICHIAS Corporation)

Esco's Approach to Environmental Issue

Energy savings and cost reductions are achieved through refrigerant replacement.

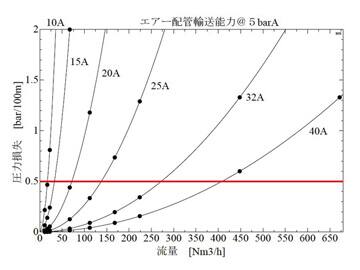

Cost reduction of fluid equipment

We optimize piping and fluid transport systems based on accurate hydraulic calculations (pressure loss calculations), design pumps, cooling towers, compressors, etc., and control the number of air compressors to reduce operating costs.

Air energy saving

We conduct surveys and make proposals for optimizing air utilization and energy conservation.

Hydraulics

We perform optimization and economic studies based on piping pressure loss and flow velocity.

Piping and equipment installation

Painting work

This is a construction of painting or spraying paint on a structure. Roof insulation coating, for example, can now be done at a low cost and reduce air conditioning costs.

Thermal insulation work

This is construction work to prevent heat from flowing out from equipment, piping, building walls, etc., and from entering from the outside. It is vital for energy conservation and the prevention of global warming.

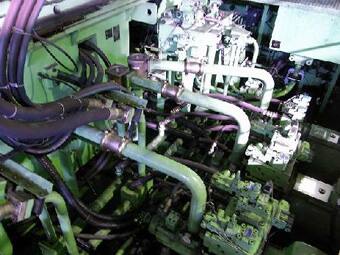

Mechanical connection work

This construction work is for connecting piping used to transport various fluids with machinery. Various types of piping materials are used depending on application and conditions, such as fluid, temperature, and pressure. It has various specifications based on welding and screwing of metal piping.

Hydraulic System

Hydraulic systems are widely used as a method of energy transmission and are used in familiar applications such as automobiles, aircraft, construction machinery, and sluice gates. Hydraulic systems are compact and can move and operate heavy objects compared to other transmission methods, such as electricity or mechanical (gear) systems.

Pneumatic Systems

This system uses compressed air to drive various machines and control machines.

Temperature control equipment

Temperature control equipment is equipment that adjusts the temperature to a constant level. Air conditioning equipment is one type of temperature control equipment. Various types of temperature control equipment are used in plant facilities.

Cooling facilities

While a refrigerator cools to a temperature lower than room temperature, equipment that cools down to room temperature is called cooling equipment. Cooling facilities include cooling towers, cooling water circulation facilities using cooling towers, air cooling fans (air fin coolers), and cooling facilities using seawater, etc. They are widely used in factories and plants and in secondary cooling facilities for refrigeration equipment.

Cooling equipment

A machine used to maintain a temperature lower than room temperature is called a chiller. Refrigeration units are heat source equipment (heat source machines) that apply heat pumps to transfer heat in order to lower temperatures, and there are several types. A heat pump is a machine that pumps heat, using a refrigerant to take heat from a low-temperature heat source (the intended object) and dump it into a high-temperature heat source (such as water or air).

Heat exchanger

A heat exchanger is a device that efficiently transfers heat from a hotter object to a cooler object. It is a device that transfers heat between two fluids through a metal or other bulkhead. Radiators, oil coolers, and intercoolers in automotive applications are heat exchangers. The device is used in various heating and cooling processes in industry, such as power plants and refineries. It is also used in air conditioners, refrigerators, freezers, and water heaters.

Boiler Equipment

A boiler facility is a machine that heats water and produces hot water or steam using gas/oil/coal, etc., as fuel. Boilers are used as heating sources in heating, factories, and plants because hot water and steam are safe and convenient for continuously obtaining heat at a certain temperature and constant pressure. Types of boilers include water tube, forced circulation, once-through, cylindrical, vertical, smoke tube, marine, and locomotive types.

Air Conditioning Equipment

Air conditioning equipment controls temperature, humidity, air purification, and airflow for people's comfort and is officially called “air conditioning equipment.” Generally, the equipment called an air conditioner controls temperature with heating and cooling installation. Recently, humidity control and air purification functions have been added to some air conditioning systems.

Water treatment facilities (water supply and drainage)

Feed water treatment facilities include various facilities and equipment, such as water purification equipment to supply high purity water, water treatment equipment such as water softeners to remove minerals before supplying water to boilers, oxygen absorbers, filtering equipment to remove foreign substances, strainers, and others. Wastewater treatment facilities treat dirty water (domestic and industrial wastewater) into clean water that does not affect the environment. The main types of treatment are physico-chemical and biological.

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00〜17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://nsx.co.jp/english/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8:00〜17:00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://nsx.co.jp/english/ |