Maintenance Management System with Digital Twin, Generated AI and Wi-Fi Vibration Sensor

Wi-Fi Vibration Sensor gconanairh combining

EWi-Fi Vibration Sensor Conanair's feature detects wear and tear on machinery and equipment components, notifies abnormalities before trouble occurs, and manages sensor signals centrally via a browser

And

EThe system configuration with INTEGNANCE VR, which can represent a factory in a virtual space using digital twin and generative AI

enables the construction of a manpower-saving system for maintenance management.

What is INTEGNANCE VR

INTEGNANCE VR from Brownreverse Inc. supports labor-saving and on-site work reform in maintenance operations at plants and factories by building plants and other facilities in a virtual space, making it easy to check the site online. The most remarkable feature of the gFast Digital Twinh is that a plant can be represented in a virtual space in as little as three days. Fast Digital Twin is the first step toward manufacturing DX. We are a distributor of INTEGNANCE VR.

![]() Brownreverse.Inc@

Brownreverse.Inc@![]() INTEGNANCE VR

INTEGNANCE VR

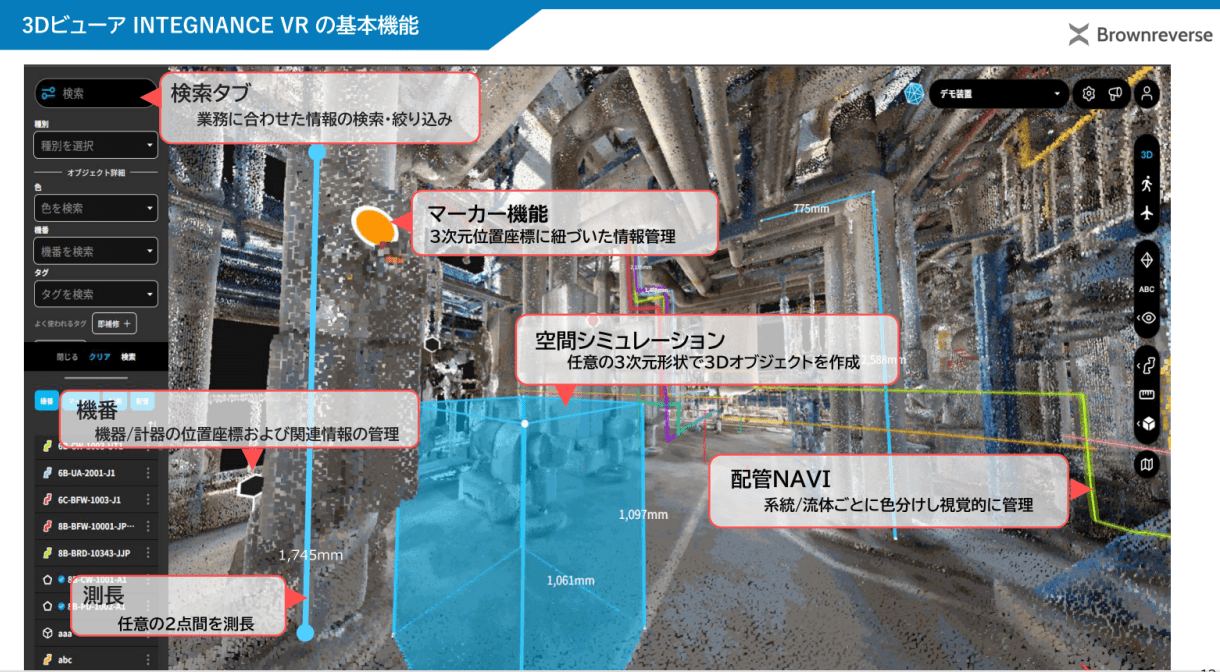

Main Functions to Streamline Operations

INTEGNANCE VR has a variety of functions that support efficient maintenance operations.

Spatial simulation

It can be used to plan scaffolding construction locations, check material delivery routes for common use and equipment renewal, and check for construction complications.

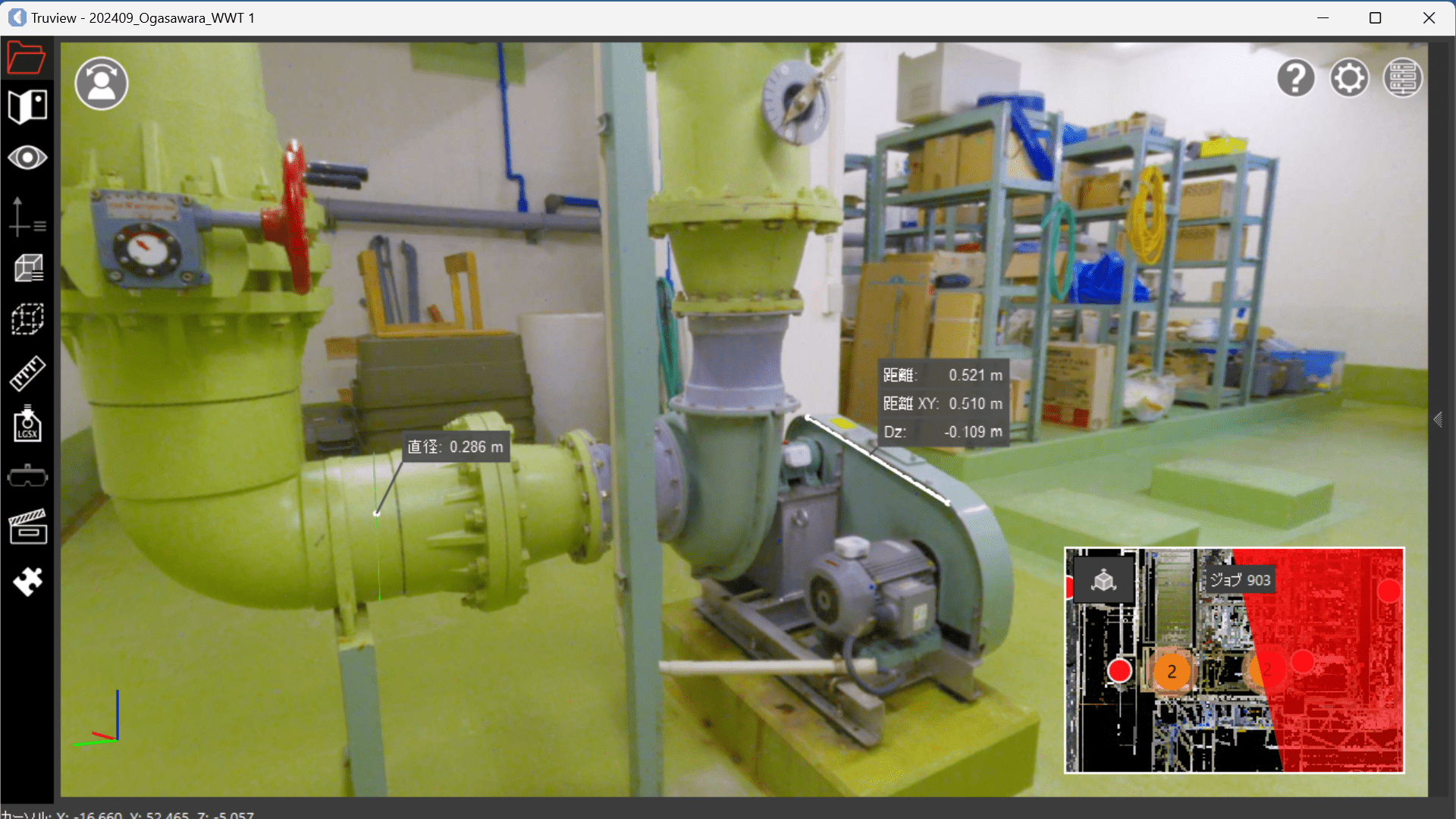

Desktop Surveying

It can survey between two points on display without deciphering drawings or measuring actual lengths in the field.

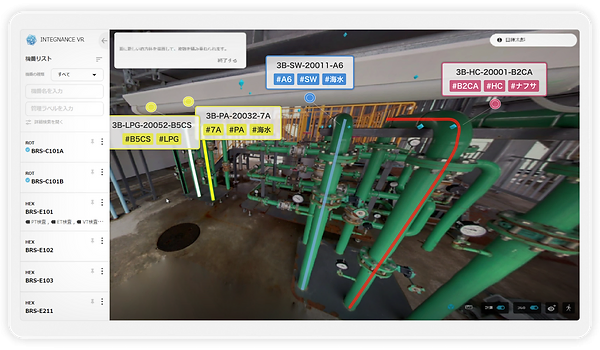

Piping NAVI

On panoramic photographs, it can map corrosion loops and corrosion/damage priority management sections.

Used Cases

Requests for rough estimates for construction/inspection can be completed online

By registering information on equipment, etc., in VR in advance, gdetails of the construction target,h gexact location,h and gconstruction routeh can be communicated online to subcontractors, significantly reducing on-site operation time. Subcontractors can use the gdesktop surveyingh and gspatial simulationh functions to obtain information necessary for rough estimates, such as the quantity of scaffolding and heavy equipment, in VR, enabling them to submit estimates to clients early.

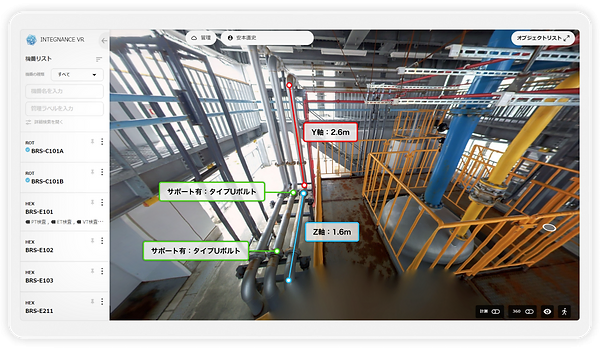

Simplified evaluation of allowable span method in VR even for seismic diagnosis work

Although there have been many cases of disasters involving piping systems, many offices have been slow to comply with seismic design standards for existing facilities. As a countermeasure, gvoluntary improvement of seismic resistanceh is necessary. Still, the burden of on-site verification work (checking the position and shape of supports, measuring the dimensions between supports, etc.) is enormous. By realizing these tasks in VR, it is possible to perform simple evaluations efficiently.

Piping management

By displaying piping to be managed (e.g., corrosion loops, oil types, short-life areas, etc.) in different colors according to purpose, checking piping on site can be eliminated, and work such as inspections and construction planning can be performed on a desktop.

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| Phone | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8F00`17F00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://nsx.co.jp/english/ |

Please contact NSXe for any issues regarding facility maintenance

| Company Name | NSXe Co.Ltd - Nakayama Hydrothermal Industry Co., Ltd. |

|---|---|

| Head Office | 7686-10 Hirano-cho, Suzuka, Mie513-0835, Japan zip code 513-0835 |

| TEL | +81-90-2189-1398 |

| FAX | +81-59-379-4704 |

| Business Hours | 8F00`17F00 |

| Office Regular

Holiday |

Saturday afternoons, Sundays and public holidays |

| URL | https://nsx.co.jp/english/ |